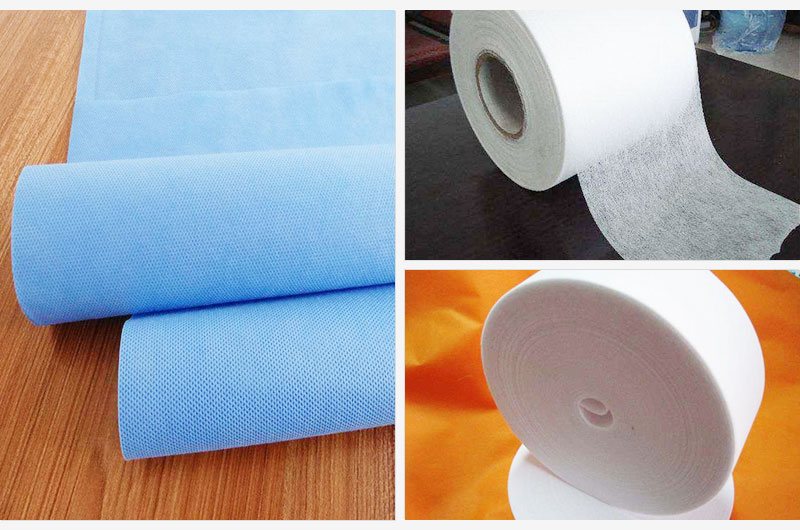

Mask raw materials–non-woven

Introduction of non-woven fabric:

Non-woven products are medical and health textiles made of chemical fibers including polyester, polyamide, polytetrafluoroethylene (PTFE), polypropylene, carbon fiber and glass fiber. They are mainly used for disposable medical treatment such as protective clothing, surgical gown Production and production of protective consumables.

Non-woven features:

1. Lightweight: Polypropylene resin is the main raw material for production, with a small specific gravity, fluffy, and good feel.

2. Soft: light dot-like hot-melt bonding molding composed of fine fibers. The finished product is moderately soft and comfortable.

3. Water repellency and breathability: Polypropylene chips do not absorb water, and the moisture content is zero. The finished product has good water repellency. It is composed of 100% fiber with porosity, good air permeability, easy to keep the fabric dry and easy to wash.

4. Non-toxic and non-irritating: The product is produced according to FDA food-grade raw materials, contains no other chemical ingredients, stable performance, non-toxic, non-odor, and does not irritate the skin.

5. Antibacterial and anti-chemical agents: Polypropylene is a chemically blunt substance, does not worm, and can isolate the erosion of bacteria and insects in the liquid; antibacterial, alkali corrosion, and finished products do not affect the strength due to erosion.

6. Antibacterial. The product is water-extracting, does not mold, and can isolate the erosion of bacteria and insects in the liquid, and does not mold.

7. Good physical properties. It is made of polypropylene spun directly into a net for thermal bonding. The strength of the product is better than that of ordinary staple fiber products. The strength is non-directional and the strength in the vertical and horizontal directions is similar.

8. Easy to be environmentally friendly. The raw material of most non-woven fabrics used is polypropylene, which is easily degraded.